On-road wind and turbulence is a ongoing concern for engineers designing new vehicles. As part of a partnership with the Aiolos Engineering Corporation and BMW, one York University engineering professor and his research team are building a new system to produce realistic turbulent flows around vehicles, the first of its kind.

Professor Ronald Hanson, from the Department of Mechanical Engineering at the Lassonde School of Engineering, has partnered with Aiolos Engineering Corporation to develop methods for simulating on-road wind and turbulence conditions in an automotive wind tunnel. Aiolos is a Canadian firm specializing in the design and construction of wind tunnels and test facilities, primarily for the automotive and aeronautical industry.

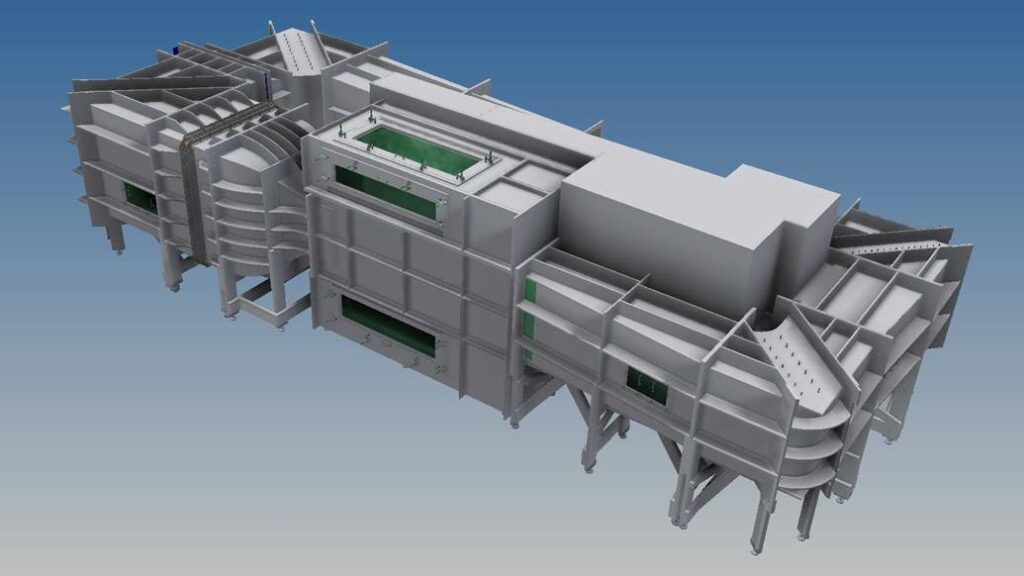

Aiolos is presently involved in the design and construction of a full-scale wind tunnel in Munich, Germany for the automobile company BMW. This wind tunnel is designed to have a state-of-the-art acoustic environment with very low background noise to allow the aerodynamic noise generated by the vehicle to be investigated, both inside and outside of the vehicle. As part of this project, Aiolos designed and constructed a model scale wind tunnel to develop and validate elements of Aiolos’ design for the full-scale facility.

Aiolos and BMW have donated this new model scale wind tunnel to Hanson. The scale model is nearly 10 metres in length and valued at approximately $500,000. Hanson and his team of researchers recently installed the wind tunnel at the new Lassonde Research Centre at 4751 Keele St., where experiments were performed to optimize the wind tunnel design to meet the high-performance requirements of the full-scale wind tunnel. The wind tunnel was visited by Aeroacoustics Specialists from BMW in September 2021.

Historically aerodynamic wind tunnels, used by vehicle designers for the development of the aerodynamic shape of their vehicles, provide a very stable, uniform flow around the vehicle. But these test facilities have not had the ability to simulate the very unsteady flows that typify real-world driving. On-road turbulence conditions affect the steady state aerodynamics, the dynamic characteristics and aerodynamic noise generation for the vehicle.

Through an NSERC Alliance Grant with Aiolos, Hanson and his team of graduate students are building a new system for the nozzle of the model wind tunnel to produce realistic turbulent flow conditions for the vehicle, with gusts and unsteady yaw motions of the airflow being part of the mix. This complex hybrid system consists of actuated diamond vanes and airfoil sections at the nozzle exit that the flow must pass through before entering the testing section of the wind tunnel. Fifty-four independent motors will be used to actuate the various sections of the vanes and airfoils to produce a range of realistic unsteady flow conditions. When completed this system will be first of its kind.

“We’ve been working on the design of this system for several months,” said Hanson. “The result will be a wind tunnel that has a broad testing range of flow conditions, and the extent to which we can tailor the flow.”